By Robert T. Furst

This Consumer Information Guide is designed to provide piano customers

with an unbiased point of view into the construction of pianos. This

information should be of help to identify the quality of a given piano

and is intended to eliminate wild and exaggerated claims of quality and

merit in others.

There is clearly disparity in pianos, differences in proficiency and

tone, but there is a very identifiable unifying thread which runs

through all good pianos. That thread not only is a desire for

excellence, it is also a sense of understanding and the impact of music

in our lives. The evidence of this good and the enjoyment of a truly

good piano is tangible. We welcome the opportunity to share it with you.

Sincerely,

Robert T. Furst

Creator, Founder & Executive Director

Creator, Founder & Executive Director

National

Piano Institute

Copyright 1990 © Robert T.

Furst -

All Rights Reserved

Back to top

of page

NATIONAL PIANO INFORMATION

CENTER

CONSUMER INFORMATION GUIDE

Pianos are manufactured in two ways. The important difference between

pianos is the amount of time spent in assembling the various parts into

the case and bringing individual instruments up to their final tone

quality. Pianos manufactured in this traditional manner may take from

nine months to a year to put on the finishing touches. Workers

throughout the generations of piano builders were taught the ways and

techniques of their trade by the elder craftsmen - it was the only way -

because until just recently there existed no blueprints showing how the

best pianos were built. Each craftsman uses only his own un powered hand

tools on "his" piano - beginning its life and seeing it to finished

construction. Each piano reflects the ability and tonal ideas of its

maker. This is why pianos of the same model and make all sound so

different from each other.

Although less expensive, two lines of well made, elegantly styled and

beautifully finished pianos have in the past few years enjoyed more

recognition as a very fine value in Japanese-made instruments. Although

less expensive than the best known American brands, they have set

challenging standards to all others in the world, they are the Kawai and

Yamaha. Their factories boast the latest in modern state-of-the-art

production techniques, such as computer controlled drying chambers that

monitor the humidity content of all wood materials used, and laser beam

guidance systems that make precision fitting of all parts tolerant to

one six-thousandth of an inch, the use of space age plastics such as ABS

Styran that will never be effected by moisture and outlast wood.

Initially, the traditional manufacturers attacked this kind of building

philosophy an economic sellout to the pressures of modern mass

manufacturing. Kawai and Yamaha do indeed represent the answer to

Baldwin, Mason & Hamlin and Steinway, and parallels between them have

already been well established.

Kawai and Yamaha both have very logical

organized factory outlets and super-efficient production processes and

both share a philosophy of machine over man wherever perfection is desired

and cost effectiveness to the consumer is a consideration.

The proof of the pudding ... as the saying

goes or as the traditional manufacturers claim, yes, the Yamaha lacks

depth of tone when compared with the very best, not so with Kawai, whose

tone is said to have a fine, luminous tone, reminiscent of a Viennese or

German piano, yet it is a tone of full brilliance and depth when required

by professions everywhere. As with Yamaha, Kawai's virtues are the

undeniably consistent attention to overall design parameters such as the

construction of the inner parts, fit and finish, and dependable evenness

of touch responsiveness which is always made to 100 percent consistent

specifications from piano to piano.

The fame and reputation of pianos such as

Bechstein, Bosendorfer, Grotrian as with Steinway, lies principally in the

construction of concert grand pianos. We must seriously question the

practicality of buying the smaller models, since generally they do not

represent a very good value to the consumer for the price. Because without

the longer strings and soundboard area of at least the semi-concert grand,

they do not demonstrate the famous qualities of tone which are readily

recognized in the larger models. In addition there are very limited

advantages to hand crafted instruments in a smaller size, since most of

the subtle refinements these manufacturers lavish upon their pianos are

not readily apparent to ear or fingers. This same statement holds true to

other European imports such as Ibach, Seiler, Schimmel or Erard. They are

all very fme instruments in their own right, but questionable as to

investment value in the smaller piano category.

Back

to top of page

INVESTMENT (I.Q.) QUALITY

Investment quality is based on a variety

of factors, the most important of which are price; styling; brand

name; availability; service; and perceived determinants of quality such

as tone, tuning stability, workmanship, beauty, and durability. In 1974

the average price of a quality well known console piano was $1,246, both

imported and domestic. They are:

|

BRAND |

SIZE |

PRICE |

BRAND |

SIZE. |

PRICE |

|

Baldwin |

41" |

$1,470 |

Sohmer |

41" |

$1,415 |

|

Cable-Nelson

|

41" |

$ 945 |

Steinway |

40" |

$2,774 |

|

Cline |

40" |

$1,295 |

Story&Clark |

40" |

$ 945 |

|

Kawai |

41" |

$1,064 |

Weber |

40" |

$ 850 |

|

Kimball |

42" |

$ 900 |

Wurlitzer |

42" |

$1,395 |

|

Krakauer |

41" |

$1,210 |

Winter |

40" |

$ 925 |

|

Schafer&Sons

|

42" |

$1,185 |

Yamaha |

42" |

$1,075 |

During 1989, fifteen years later, any of the

pianos listed above used in good condition will resale for between $1,500

and $4,400 depending on make and model. In all cases the pianos listed

above have appreciated in value.

The two major producers in Japan, Kawai and

Yamaha used the following approach to enter the U .S, market. Each offered

a limited selection of moderately-priced, good quality uprights and grand

pianos in 1960. Over the next two decades each upgraded the quality of its

pianos and broadened its range of price points, models, and styles. In

addition they expanded their technical and educational services to

dealers, piano tuners, teachers and potential customers.

Three Korean producers began exporting to

the U.S. market in 1978 (Samick), 1980 (Young Chang), and 1981 (Sojin).

Korean producers quickly began emphasizing low-end grand pianos. By 1984

grands constituted 47% of pianos from Korea, compared with 35% of the

pianos imported from Japan, and only 4% Shipped by U.S. producers. Grand

pianos are more labor intensive than vertical pianos.

Back

to top of page

According to the U.S. Department of Labor

applying average hourly labor rates to the typical number of man hours

required to build a grand piano in the United States labor cost was

$1,886.40. Compared to $931.20 in Japan and $195.20 in Korea. In addition

Korea has long enjoyed most favored nation status, giving the Korean

producers a greater cost advantage than the U.S. or Japanese producers.

It is a well established fact that all good

pianos will hold their value or will appreciate in value. The same fact

applies to the Korean piano of the present, any statement opposing this

view are usually born of competitors defeat and not worthy of

consideration.

Buying a piano is a matter of eye and ear

combined, plus the character of the merchant who sells it, backed by the

manufacturer. The prospective buyer of a piano should deal with a local

dealer familiar with the instruments, and if he is honest and reliable you

may depend on what he tells you concerning them. The three essentials to a good piano are tone,

touch, and durability. Next is the beauty of case design. The standard

cases are made of veneers of walnut, oak, fruitwood and pecan. Pianos such

as ebony, white, and ivory are very popular and easy to care for. Durability is important. The manufacturers

warrantee covers that and the dealer will endorse the manufacturer.

If you are an aspiring artist or a professional musician, you should buy

the largest piano you have space for and the finest built in your own

estimation. The piano should have nothing less than complete artistic

capabilities. The extra cost will not amount to much when spread over the

years, and you will receive the extra benefit of owning and playing a

piano of superior quality.

On the other hand, pianos of lower cost are

more likely to be made out of lower cost materials and will be more

difficult to service or keep in tune. A piano requires skilled

craftsmanship and superior materials to build which takes years of

experience and know how to develop. A piano is a precision engineered

musical instrument. The strings are pulled to high tension (average 170

pounds per string, 220 strings, total tension, about 40,000 pounds of

tension, about the combined weight of nine full sized automobiles). The

back posts and cast iron plate work in concert to support this tremendous

tension of the strings. The reasons why it is necessary to have the

strongest structure possible to support string tension is:

1. To prevent the back of the piano from warping

and twisting.

2. To enable the piano to stay in tune.

3. Without this solidarity in the structure the many parts of the piano

could not function properly.

We have examined the various materials used in

each piano and the manner in which they are used. We have subjected each

piano to various tests in tone and touch, and we have judged the

aesthetics of the outer case and inner workings of each instrument by

actual inspection of production models on dealer floors, as well as the

critical analysis of the published specifications and general information

provided in manufacturers brochures. All of these factors have been

considered in this analysis of pianos sold in the United States.

Ten features have enabled us to establish a

criterion for grading and measuring the quality of a given piano line.

These ratings reflect consistency in the quality of all instruments

bearing a particular brand name and are an average of all instruments

bearing that name.

We use the formula of one point for each

feature that meets or exceeds our criterion, and deduct one point for each

feature that does not meet our requirements. This should serve as a guide

if you wish to conduct the same test for a particular piano.

Back

to top of page

QUALITY [Q.R.] RATING

THE BASIC STRUCTURE:

The following information was compiled to

evaluate the general specifications as listed by individual manufacturers,

and will enable us to establish a criteria in our analysis.

A. THE BACK POSTS:

· Size of the post; not only width

but depth.

· Double or triple posts

· Posts extend all the way to the

top of the piano

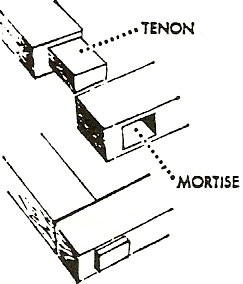

Posts extend all the way to the bottom in a tight mortise and tenion

construction.

(MORTISE - A notch, or hole shaped to fit

TENON - a projecting part for insertion into another piece to make a

joint.)

B. MATERIAL OF BACK POSTS:

· Solid spruce, not poplar / oak

· Strongest wood for its weight

· Resists splitting and cracking

· Spruce lengthwise grain is

straight close and dense provides rigid support.

· Backposts bolted to cast iron

plate

C. THE PINBLOCK:

· Quarter sawn hard rock maple,

cross laminated, 2" thick.

· Number of plies not as

important as type and cut of wood.

D. THE SOUNDBOARD:

· One thickness spruce.

· The term "Solid" referring to

spruce in soundboards is semantically misleading today because builders of

laminated boards, where all three

layers are spruce, refer to the board as

"solid" spruce, meaning it is "all" spruce.

E. SOUNDBOARD Ribs-

• Spruce ribs, quarter sawn and feathered at

each end.

F BRIDGES-

• The treble bridge should consist of solid

quarter sawn rock maple material.

• The treble bridge is glued to the

soundboard and doweled through the soundboard into each rib.

• The bass bridge should consist of solid

quarter sawn rock maple with a cantilever for tone transmission.

G.ACTION:

• Direct blow with action parts all perfectly

spaced and in line when viewed from front or side of piano, this is a

tip-off on quality, examine it closely.

• Action rails made of extruded aluminum and

a tubulous aluminum hammer rest rail.

H. STRINGING:

• Bass strings are pure copper wound, not

copper dipped.

• Longest string length (speaking length)

Strings should be perfectly spaced (none

touching) just below bearing bar. Tip-off to quality.

I. CASE PARTS:

• Side, arm, leg base and lower end pieces

all glued together to form a solid, single (homogeneous) unit.

• Keycover (fall board) is grand type,

hinged, not slide out. Key slip should match perfectly, both should be

easily removed for servicing.

• Casters heavy duty, either hard rubber or

solid brass, free moving.

• Pedals should be solid brass, not brass

capped, three in number, drop type for comfort soft (una corda), loud

(sustaining), and sostenuto or a practice pedal (muffler).

• Case parts should be fmished without any

visible flaw even in critical light, no small ripples in finish, no running

of varnish on inside of cabinet.

J. THE KEYBED:

• The keybed should consist of at least four

panels with tongue and groove construction. It should be unglued to allow

for expansion and contraction.

• The

material in the keybed is spruce.

Back

to top of page

Quality (Q.R.) and Investment (I.Q) Rating

BRAND NAME

MANUFACTURER Q.R.

I.Q.

RETAIL PRICE

|

Acrosonic |

Baldwin |

10 |

10+ |

$3,542 - $4,265 |

|

Astin - Weight |

|

10 |

10 |

$4,780 - $5,500 |

|

August Forster |

(European) |

10 |

4 |

$18,500 - $34,000 |

|

Baldwin |

|

10 |

10 |

$2,460 - $32,500 |

|

Barock |

(Japan) |

7 |

4 |

n/a |

|

Bechstein, C. |

(European) |

10 |

8 |

$10,000 - $55,000 |

|

Becker |

Kimball |

6 |

3 |

$1,395 |

|

Blessing |

(Chinese) |

4 |

2 |

n/a |

|

Bluthner |

(European) |

10 |

7 |

n/a |

|

Bosendorfer |

(European) |

10 |

8 |

$14,300 - $69,600 |

|

Charles R. Walter |

|

10 |

10 |

$4,700 - $5,500 |

|

Classic Player |

Pianos |

10 |

10 |

$8,995 |

|

Diapason |

Kawai |

10 |

8 |

$4,650 - $14,900 |

|

Falcone |

Falcone |

10 |

10 |

n/a |

|

Everett |

Yamaha/Everett |

8 |

8 |

$3,700+ |

|

Fazer |

(European) |

10 |

8 |

n/a |

|

Feurich |

(European) |

10 |

6 |

n/a |

|

Hamilton |

Baldwin |

10 |

10 |

$4,400 - $4,800 |

|

Handok |

(Korean) |

6 |

3 |

n/a |

|

Ranil |

(Korean) |

6 |

3 |

n/a |

|

Hanover |

(Chinese) |

4 |

2 |

n/a |

|

Heintzman |

(Canadian) |

10 |

7 |

n/a |

|

Hinze |

Kimball |

4 |

2 |

$2,100 |

|

Hohner |

(European |

3 |

2 |

$2,000 |

|

Howard |

Baldwin |

6 |

7 |

$7,800 - $9,600 |

|

Hsing Hai |

(Chinese) |

4 |

2 |

n/a |

|

Hyundai |

Samick (Korea) |

6 |

6 |

$7,500 - $9,700 |

|

Ibach |

(European) |

10 |

9 |

n/a |

|

Jasper- Kimball |

0 |

3 |

3 |

$2,000 |

|

Kawai |

(Japanese) |

10 |

10+ |

$3,840 - $43,200 |

|

Kimball |

|

7 |

9 |

$1,900 - $14,300 |

|

Knight |

(European) |

10 |

8 |

$4,500+ |

|

La Petite |

Kimball |

6 |

9 |

$6,700+ |

|

Maeari |

Samick (Korean) |

6 |

6 |

n/a |

|

Mason & Hamlin |

Sohmer |

10 |

10+ |

$5,600 - $27,000 |

|

Nieer |

(Chinese) |

2 |

2 |

$1,800+ |

|

Pearl River |

(Chinese) |

2 |

2 |

$1,500 - $2,100 |

|

Petrof |

(European) |

8 |

8 |

$3,800 - $12,000 |

|

Rippen |

(European) |

7 |

5 |

$3,200 |

|

Samick |

(Korean) |

9 |

9 |

$2,600 - $29,700 |

|

Schafer & Sons |

|

10 |

10 |

$2,500 - $32,000 |

|

Scheidmeyer |

Kawai (Japanese) |

10 |

10 |

$5,700 - $21,000 |

|

Schimmel |

(European) |

10 |

10 |

$7,500 - $42,000 |

|

Schumann |

Samick (Korean) |

8 |

6 |

$3,000 - $14,000 |

|

Seiler |

(European) |

10 |

10 |

n/a |

|

Sherman Clay |

Sojin (Korean) |

10 |

9 |

n/a |

|

Sohmer |

|

10 |

10 |

$5,600 - $28,000 |

|

Sojin |

(Korean) |

10 |

9 |

$2,500 - $29,000 |

|

Steinway & Sons |

|

10 |

10+ |

$6,800 - $46,000 |

|

Tadashi |

(Japanese) |

10 |

7 |

n/a |

|

Tokai |

(Japanese) |

10 |

7 |

n/a |

|

Toyo |

(Japanese) |

10 |

7 |

n/a |

|

Weber |

Young Chang (Korean) |

8 |

9 |

See Young Chang |

|

Wurlitzer |

Baldwin |

7 |

10 |

$2,800+ |

|

Yamaha |

(Japanese) |

10 |

10+ |

$3,500 - $43,000 |

|

Young Chang |

(Korean) |

10 |

9 |

$2,700 - $32,000 |

|

|

|

|

|

|

|

+

Indicates best known

brand names and better resale value |

Copyright 1990 © Robert T.

Furst -

All Rights Reserved

Robert T. Furst - Executive

Director

Founder National

Piano Institute

Back

to top of page